- #Chemical Process Simulation Jobs Free Of Charge#

- #Chemical Process Simulation Jobs Full List Of#

- #Chemical Process Simulation Jobs Code Of The#

Chemical Process Simulation Jobs Full List Of

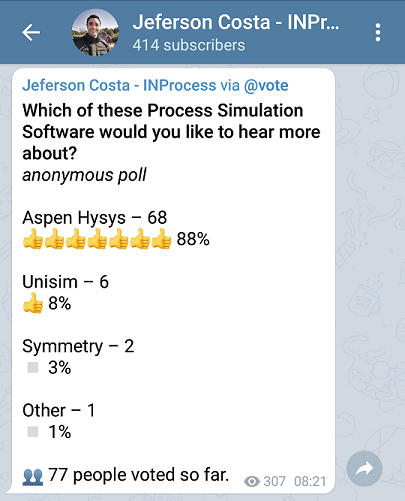

Understanding of broad chemical engineering principles and unit operations.Chemical engineers are involved in many aspects of plant design and operation, including safety and hazard assessments, process design and analysis, modeling.Steady-state and dynamic plant simulation are powerful tools that help engineers create optimal process designs to analyze plant operations, to develop performance improvement strategies, monitor and optimize operations and much more.First principles-based chemical process modeling experience (whole-process or detailed unit operation) Demonstrated facility with applied computing (e.g., Chemical Engineering simulation packages or programming languages such as Fortran, Matlab, Python, Visual Basic or C/C++) Strong verbal and written communication skillsWe are providing a full list of process simulator packages with their key characteristics. Knowledgeable/good user of simulation software’s such as Chemcad or Aspen Plus. Currently studying for your Master’s degree in Chemical or Process Engineering. Chemical Process Optimization Intern Modeling & Simulation We are looking for you.

Chemical Process Simulation Jobs Free Of Charge

The Process Simulation Specialist LSC is responsible for working with the Life Science & Chemicals (LSC) Subject Matter Experts (SMEs) to develop process simulation models that would be key to process optimization and COGs reductions. Easily apply to 529 Process Simulation Engineer Job openings on Shine.comJob Description & How to Apply Below. On this list, there will definitely be something for you:Search latest Process Simulation Engineer Jobs available across major cities in India. So, no more excuses for not using process simulation tools. While some of them are very expensive, there are as well affordable ones and even a couple of them that are totally free of charge.

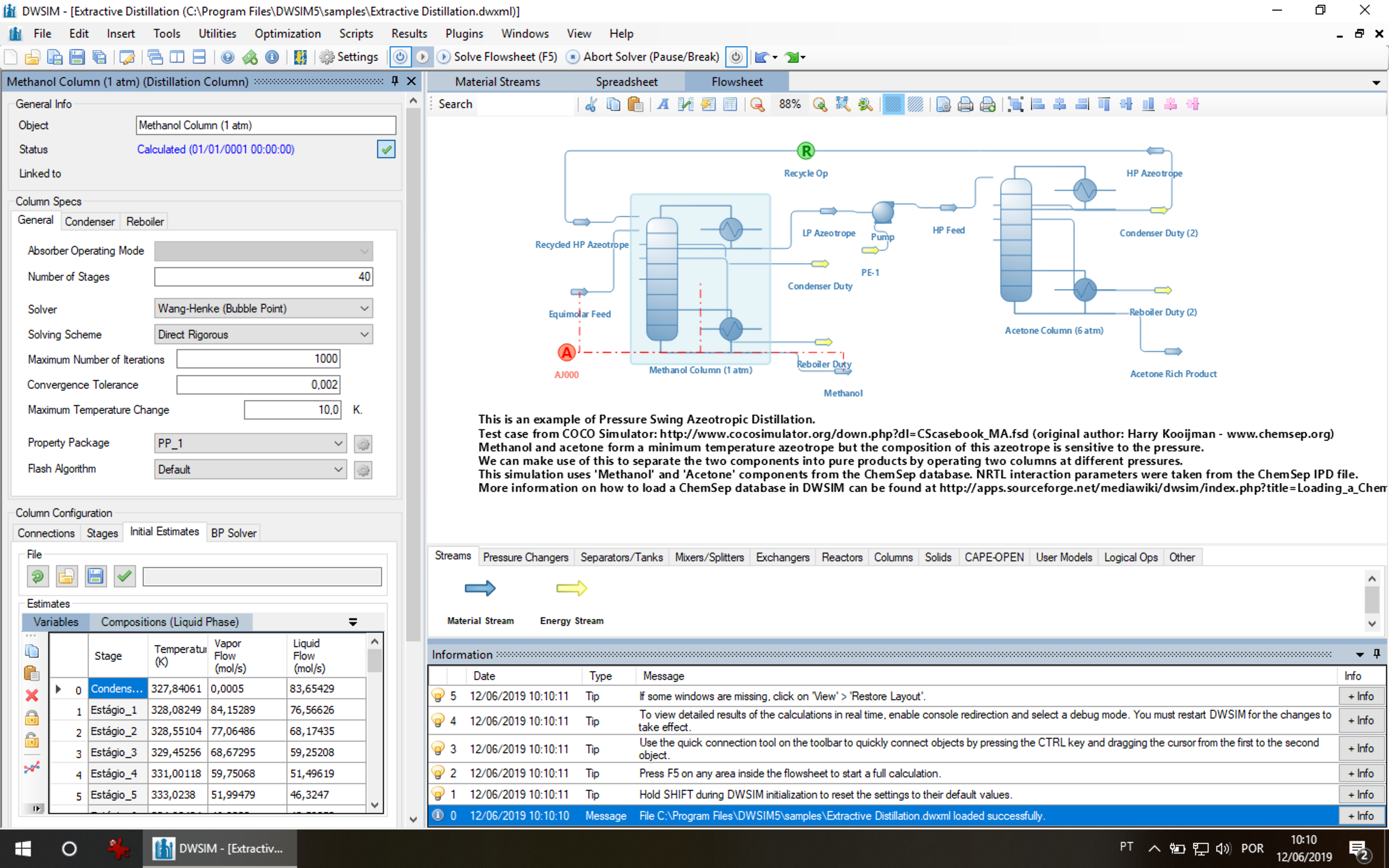

CADSIM Plus includes a comprehensive set of generic process modules and has a number of optional module libraries for various applications. CADSIM Plus can also be used to develop complex dynamic simulations with control logic and batch operations.Chemical process simulation software that includes libraries of chemical components, thermodynamic methods, and unit operations to allow steady-state and dynamic simulation of continuous chemical processes from lab scale to full scale. Ideal for users who want to design processes, or rate existing processes, in steady state. It is a first-principles dynamic chemical process simulator and a full-featured Computer Assisted Drawing (CAD) front-end in one package. Leverage modeling investments by scaling from single models to full facility flowsheets.On the market: commercial, flexible licensingCADSIM Plus is chemical process simulation software that can perform mass and energy balances and simulate dynamic conditions.

Chemical Process Simulation Jobs Code Of The

ChemSep-LITE, a limited version of ChemSep with a maximum of 40 compounds and 300 stages, can serve as an equilibrium distillation unit operation in COCO.Simulation package can be downloaded here.Design II performs complete heat and material balance calculations for a wide variety of pipeline and processing applications. It contains a splitter, a mixer, heat exchangers, pumps and reactors amongst other unit operations. The package exhibits more than 100 property calculation methods with their analytical or numerical derivatives.COUSCOUS - the CAPE-OPEN Unit-operations Simple package is shipped with COCO. COFE displays properties of streams, deals with unit-conversion and provides plotting facilities.TEA - COCO's Thermodynamics for Engineering Applications, is based on the code of the thermodynamic library of ChemSep and includes a data bank of over 430 commonly used chemicals. ChromWorksYPSO Facto is chromatographic process simulation software and allows a rational use of experimental data and simulation of standard single columns as well as complex continuous multi-column processes. A software package for the simulation of Ion Exchange processes allows simulating very different situations ranging from amino acids purification, organic acid recovery or hydrometallurgy.Based on proven technical considerations and complemented by a cost evaluation module, this powerful and user-friendly simulation tool is designed to match the approach and needs of chemists and biochemists.COCO is a cape open to cape open simulation environment with modules presented with interesting names such as: COFE - the CAPE-OPEN Flowsheet Environment is an intuitive graphical user interface to chemical flowsheeting. The possibilities are endless: operability check-out, PID loop tuning, operator training, even online process control and soft sensor functionality and is ideal for users who want to design or rate dynamic processes.

EQ-COMP is written using software tools like MS Excel and VBA. It has the ability to use a system of PlugIns where the user can embed code written in C, C++ or FORTRAN into the models.On the market: commercial, services paid per calculation basisEQ-COMP is a complex chemical engineering process simulation software tool for automatically calculating vapor-liquid equilibrium properties of pure hydrocarbons and binary and multi-component mixtures of hydrocarbons. It supports static simulation and dynamic simulation. A graphical user interface can be used to model development, simulation execution, and results visualizing. Models are written in a modeling language, so the user does not need to be a programmer.

EQ-COMP can predict phase equilibrium properties of multicomponent hydrocarbon mixtures very accurately. Q-COMP chemical process simulation software can be used for pressure vessel design, distillation column design, natural gas pipeline design and designing of other hydrocarbon handling equipment and can also be used for oil well simulation and in natural gas contract drafting. The possible components can include non-polar hydrocarbons, mildly polar hydrocarbons, non-polar inorganic gases or mildly polar inorganic gases.

It builds on and strengthens the existing capabilities of gCRYSTAL®, gSOLIDS® and gCOAS® in a systems-based approach that links product performance to process and formulation parameters. GPROMS is an advanced mechanistic process modeling tool, integrating crystallization, solids processing and oral absorption on a single platform.

0 kommentar(er)

0 kommentar(er)